Overview

Whether you are in the office, on the road or now working from home, Sensor Networks microPIMS wireless corrosion-monitoring sensors and webPIMS™ software enables you to monitor the remaining wall thickness of safety-critical equipment whenever & wherever you are.

New Changes

“The boss said we need to change our thinking, and no better time to do it than in a crisis.” These were the first words spoken during one of our recurring monthly calls with one of our customer-partners. “CAPEX budgets are being slashed, but innovation budgets are swelling … we are being asked to find ways to technologize our way out of this so we can not only get through today but be better in the future.” As weeks went by and as the COVID19 fallout became worse, these conversations became a trend during our status calls with more of our customer-partners.

As a result, in the last two months, SNI has listened to and re-tooled to better serve our customers during these transition periods. Here are a few examples:

- #1 Temporary Social Distancing to Permanent Augmentations in Manual Labor … Sites have been forced to cut back the number of bodies on site due to COVID-19 and social distancing to mitigate contagion spread. A facility which had 50 technicians on site pre-COVID19, most likely is now having to find ways to operate with a fraction, say 20% of that number to handle the workload. Due to cost pressures associated with the falling price of oil and facilities being at max capacity for storage, when social distancing goes away, many facilities are not going to be able to bring back all 50 of those technicians to save cost and efficiencies. Wireless UT sensors placed in strategic locations around the facility using risk-based inspection methods and data from online monitoring can help reduce the number of inspectors inside the facility’s gate.

- #2 Fewer people on site means less opportunities for a safety-related injury or incident. … As safety remains job #1 for everyone, having fewer people inside the gate is a safety benefit. Using microPIMS remote ultrasonic wall-thickness sensors equates to having fewer people physically taking manual UT readings.

- #3 Scale & Technology Deployment … The hardest aspect of new technology, especially in an industrial setting, is efficient and effective deployment. We are working cross-functionally with our customers to find ways for this critical data to be shared and made actionable. As a technology company, SNI is working with a several asset owners and partners to find the safest and most cost-effective way to deploy this technology. Training on-site SMEs, preferred contractors, remote diagnostics, and giving the tools to install, relocate, trouble shoot, or otherwise control everything hardware and software. If SNI cannot be there, we will empower local experts or SMEs to be able to do the job with ease.

- #4 CAPEX to OPEX … for those who do not or will not have access to CAPEX funding for equipment in 2020 and possibly beyond, SNI started offering subscription packages whereby pay-per-sensor would now be an option versus up-front purchases. This has allowed for faster turnaround and fewer levels of bureaucracy to facilitate deployment when operators need it most.

Data that benefits multi-functional teams

In a facility there are a number of different functions who can put this data to work. Below is an actual example of how one asset owner was able to work cross-functionally and use wireless UT data to extend the life of an area of the plant (Sulphur Recovery Unit – SRU) which for years was deemed a ‘bad actor’.

- Inspection Department – During a routine, time-based inspection, a corrosion scan of a few critical locations in the SRU were identified to have localized thinning since the last inspection (2 years). The inspection team notified the corrosion team to see if they could pinpoint what might be happening to cause the thinning since the last inspection.

- Corrosion Engineers – The corrosion team looked at the operational data since the previous inspection and had a few hypothesis on what may be happening (amine corrosion). However, without extremely precise and timely data, this hypothesis could not be tested. The corrosion team then went to their water & chemical team to see if they had additional data points which might help.

- Water & Chemical – The water and chemical team looked at the dosage of inhibitor used over the course of the inspection interval to see if they could zero in on any changes which might have caused issues. In doing so, they teamed up with the process/operations team to see if there had been any operational tweaks or changes over the same time interval.

- Process/Operations – After doing some research of their own, it turned out that not only had a few different operational parameters changed over the course of the inspection interval, but different feed stock had been used as well.

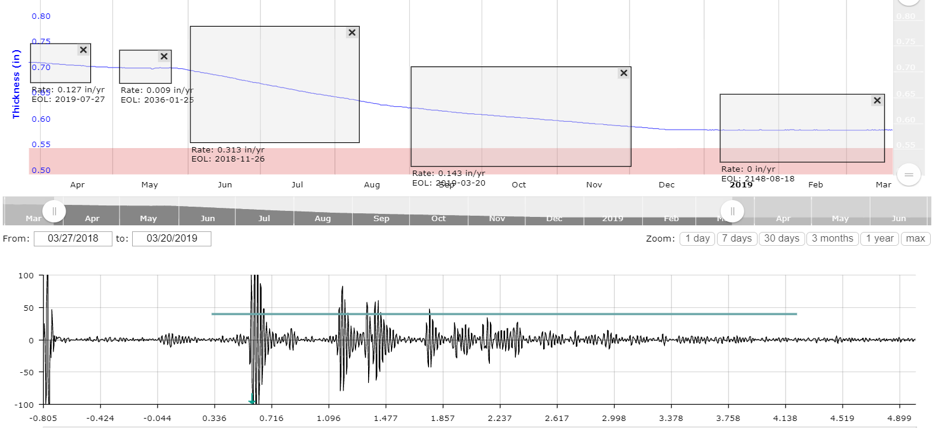

In the end, the team decided to install a number of wireless UT sensors across the different identified areas and monitor daily to see if they could get a glimpse into what was happening at the unit during different operating window. See below what they found:

What the cross-functional team found was that during different operating intervals using varied types of feed stock combined with different amounts of chemical inhibitor coupled with different operating parameters, they were able to actually identify and remediate the corrosion based on that set of defined inputs.

Our world is changing every day, and in many ways for the better. Please contact SNI to discuss how we can help make a difference in your company’s digital transformation, as we are doing for so many. We are here to work together to help you realize your potential efficiencies, cost savings, and most importantly, safety.